1.2344 H13 SKD61 tool steel flat

1. Chemical composition

| C(%) | 0.37~0.42 | Si(%) | 0.90~1.20 | Mn(%) | 0.30~0.50 | P(%) | ≤0.030 |

| S(%) | ≤0.030 | Cr(%) | 4.80~5.50 | Mo(%) | 1.20~1.50 | V(%) | 0.90~1.10 |

2. Equivalent Of 1.2344 hot work alloy tool steel

| USA | Germany | China | Japan | France |

| ASTM/AISI/SAE/UNS | DIN,WNr | GB | JIS | AFNOR |

| H13 / T20813 | X40CrMoV5-1/ 1.2344 | 4Cr5MoSiV1 | SKD61 | X40CrMoV5/Z40CDV5 |

| England | Italy | Poland | ISO | Austria | Sweden | Spain |

| BS | UNI | PN | ISO | ONORM | SS | UNE |

| BH13 | X40CRMOV511KU | 40CrMoV5 | 2242 | X40CRMOV5 |

3. Heat treatment Related

- Annealing of 1-2344 Tool steel

At first, Slowly heated to 750-780 ℃ and allow enough times, let the steel to be thoroughly heat, Then cool slowly in the furnace. Then the 2344 tool steel will get MAX 250 HB (Brinell hardness).

- Hardening of 1-2344 tool steel

1.2344 steels should be heated uniformly to 1020-1060°C. until completely heated through. And if needed, the steels can be preheated at 300-500°C (572-932°F). About 30 min per 25 mm of ruling section is to be provide and then the steels should be immediately quench in oil or air.

- Tempering of 1.2344 tool steel

At first, tempering of 1.2344 steels is performed at 550-650°C, Soak well at the selected temperature and soak for at least one hour per 25mm of total thickness. Then get Rockwell C hardness of 56 to 38.

Temperature [℃] 400 500 550 650

Hardness [HRC] 53 56 54 47

4. Mechanical Properties

The mechanical properties of 1.2344 tool steels are outlined in the following table.

| Tensile strength, ultimate (@20°C/68°F, varies with heat treatment) | Tensile strength, ultimate (@20°C/68°F, varies with heat treatment) | Reduction of area (@20°C/68°F) | Modulus of elasticity (@20°C/68°F) | Poisson’s ratio |

| MPa | MPa | Gpa | ||

| 1200-1590 | 1000-1380 | 50% | 215 | 0.27-0.30 |

5. Applications

And 1.2344 steels are mainly used for forming extrusion dies. Typical applications include casting molds aluminum, magnesium, zinc, copper and aluminum extrusion dies, liners, spindles, pressure pad, followers, pad, die, the death and the adapter ring copper and brass extrusion.

Moreover, 1.2344 is used to produce hot stamping and extrusion die forging, thermal upsetting dies, jigs mold, hot embossing, punching, trimming tools. Other applications include plastic molds, shear blades for heat and hot extrusion dies.

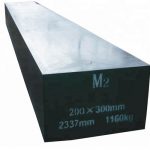

6. Regular size and Tolerance of DIN 1.2344 tool steel

DIN 1,2344 Steel round bar: Diameter Ø 5mm – 3000mm

1.2344 Steel plate: Thickness 5mm – 3000mm x Width 100mm – 3500mm

Steel Hexagonal bar: Hex 5mm – 105mm