Inconel 601 is a nickel-chromium alloy with an addition of aluminum for outstanding resistance to oxidation and other forms of high-temperature corrosion. It also has high mechanical properties at elevated temperatures. A construction alloy for heat treat furnace fixtures and components such as annealing tubes, muffles, flame shields.

| ASTM Specification | ASTM B 167 ASME SB 167 / ASTM B 829 ASME SB 829 / ASTM B 517 ASME SB 517 |

|---|---|

| Standard | ASTM, ASME, JIS, AISI, AMS, EN, SAE, DIN, NF, TOCT, DS, DTD, GB |

| ASTM B167 inconel 601 Seamless Pipe Size | 4 to 219mm W. T.: 0.5 to 20mm |

| UNS N06601 Welded Pipe Size | 5.0 - 1219.2 mm |

| Inconel WERKSTOFF NR. 2.4851 EFW Pipe size | 5.0 - 1219.2 mm |

| Swg & Bwg | 12 Swg., 10 Swg., 16 Swg., 14 Swg., 20 Swg., 18 Swg., |

| 601 Inconel Pipe Schedule | XS, SCH30, SCH40, XXS, SCH80, SCH120, SCH60, SCH140, STD, SCH10, SCH10S, SCH40S, SCH80, SCH20, SCH5, SCH160 |

| inconel 601 pipe Length | Double Random, Single Random, Standard & Cut length Pipe |

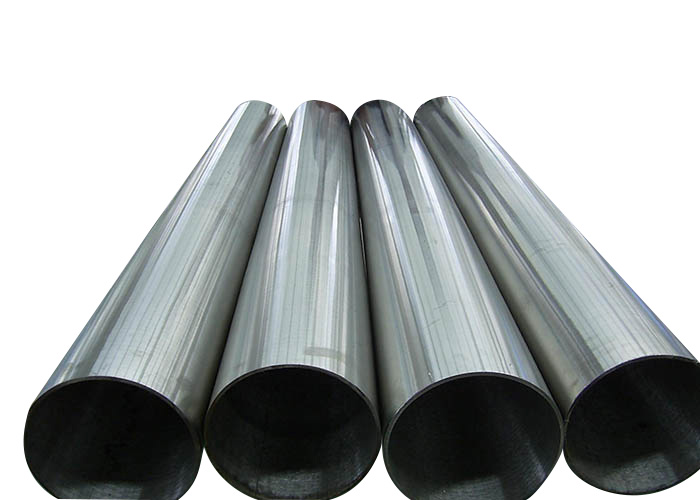

| Finish | Polished, AP (Annealed & Pickled), BA (Bright & Annealed), MF, NO.1, NO.4, 2B, BA, HL, 8K, Mirror finish, etc |

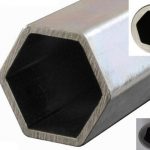

| Form | inconel 601 are available in form of Round, Square, Hollow, Rectangular, Hydraulic, Coiled, Straight Pipes, “U” Shape, Pan Cake Coils etc. |

| Type of 601 Alloy Pipe | Seamless / ERW/ EFW / Welded / Fabricated / CDW / DOM / CEW inconel 601 |

| inconel 601 pipe End | Plain End, Beveled End, Treaded Pipe, Screwed ends |

Chemical Composition, %

Ni | Cr | Al | C | Mn | Si | Fe |

|---|---|---|---|---|---|---|

61.5 | 22.5 | 1.4 | .05 | .3 | .2 | 14 |

Mechanical Properties

Typical room temperature Properties

Tensile (psi) | .2% Yield (psi) | Elongation (%) |

|---|---|---|

80,000 | 30,000 | 35 |

ASTM B163 B167 ASME SB163 SB167 N06601 Inconel 601 Tubing DIN 17552 2.4851 is a nickel-chromium alloy used for applications that require resistance to corrosion and heat. This nickel alloy stands out due to its resistance to high temperature oxidation, remaining highly resistant to oxidation through 2200 °F. Alloy 601 develops a tightly adherent oxide scale which resists spalling even under conditions of severe thermal cycling. This nickel alloy has good high temperature strength, and retains its ductility after long service exposure.

ASTM B163 B167 ASME SB163 SB167 N06601 Inconel 601 Nickel Alloy Seamless Tubes Tubing Pipes has good resistance to aqueous corrosion, high mechanical strength, and is readily formed, machined and welded. Inconel 601 2.4851 properties make it a material of broad utility in fields like thermal processing, chemical processing, pollution control, aerospace, and power generation. However, alloy 601 2.4851 is not suggested for use in strongly reducing, sulfur bearing environments.

ASTM B163 B167 ASME SB163 SB167 N06601 Inconel 601 Nickel Alloy Seamless Tubes Tubing Pipes 2.4851 Characteristic as below:

1.Excellent inoxidability in the high temperature.

2.Good resistance to carbonizing.

3.Good inoxidabilitiy in sulfur atmosphere

4.Good mechanical properties in both room temperature and high temperature.

5.Good resistance to stress corrosion cracking, 601 have high creep rupture strength since it limits the carbon content and grain size, so recommend to use for above 500℃ environment.

ASTM B163 B167 ASME SB163 SB167 N06601 Inconel 601 Nickel Alloy Seamless Tubes Tubing Pipes 2.4851 Metallurgical structure: 2.4851 alloy 601 is face-centered cubic lattice structure.

Inconel 601 2.4851 Corrosion resistance: One of the mainly performance of 601 is inexorability in high temperature, even in very inclement conditions. If in the process of heating and cooling cycle, 601 can generate the dense layer of oxide film to get high spalling resistance. 601 have good carbonation resistance. With excellent inoxidability in the high temperature of sulfur atmosphere since it has high chromium and aluminum content.